Colloid Mill MK

The IKA MK 2000 is a high-performance inline colloid mill capable of performing wet and fine milling of tough and grainy raw materials. The MK 2000 is especially suitable for the production of colloidal solutions or extremely fine emulsions and suspensions. Excellent dispersing performance allows the IKA Colloid Mill MK 2000 to be used for continuous processes, providing a narrow distribution range of ground particles in a single pass. For challenging milling tasks the colloid mill can be installed into a recirculation loop with a working vessel by means of tube connections.

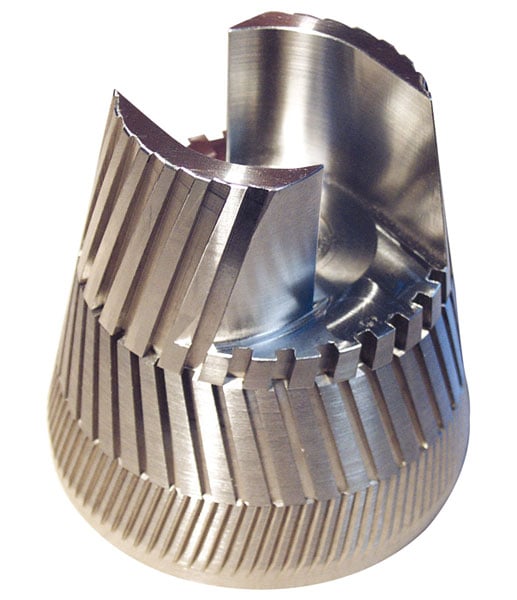

For optimum adaptation of the machine to the process it can be equipped with different milling tools. The spiral geared as well as cross geared tools are available.

The conical geometry of the milling tools enables an axial displacement of the stator for an infinite adjustment of the milling gap. This allows influencing the dispersing effect, particularly regarding tasks with variable raw materials.

As neither the rotor nor the stator is slotted throughout, the probability of particles passing through the generator untreated is negligibly small. These collective features enable the IKA Colloid Mill MK to achieve the finest particle size reduction, thereby contending with a high pressure homogenizer by attaining similar dispersing results at higher flow rates.

The IKA Colloid Mill MK 2000 is available in seven different sizes, with varied possible throughput from 200 to 80.000 l/h. All machine sizes can work with the same circumferential rotor speed, which ensures reliable scale-up.