Colloid Mill MK

Advantages of the IKA MK 2000:

- High throughput in combination with excellent grinding result

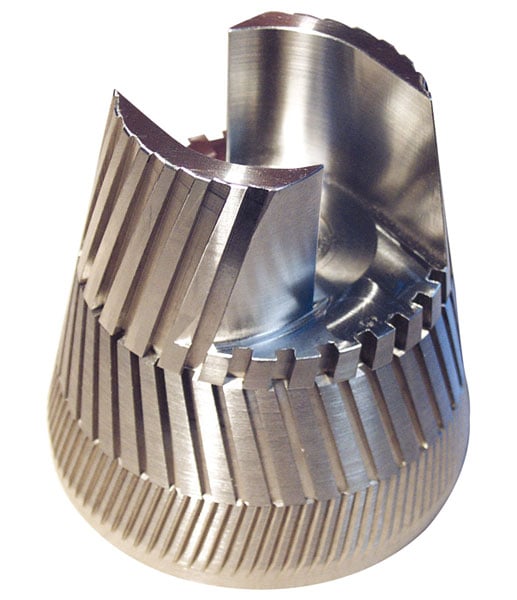

- Different milling tools to customize milling shear rates

- Infinitely adjustable gap settings between rotor/stator for control of particle size reduction

- Compactness of production systems with IKA Colloid Mill MK as a result of the inline design of the machine

- Suitable for products in a wide viscosity range, up to 50.000 mPas

- Capable of operation under pressures up to 16 bar

- Easy scale-up processes developed with the laboratory machine MK onto production machine MK

- All wetted parts are made of 316L / 316Ti stainless steel

- High-value seal with wear-resistant materials

- High quality surface finishes for easy cleaning

- Other materials and finishes are available upon request

- Machine is self-draining. CIP and SIP capable

- Low noise levels

- Manufactured according to EHEDG guidelines (European Hygienic Engineering and Design Group)

- Pharmaceutical execution available upon request

- Explosion protected executions according to ATEX 95 guidelines deliverable